12 - 13 - 12

Minor fender bender tonight at rush hour in the Fan. Just a scuff on the

bumper and one of my already-breaking eyebrows snapped a bit. Car is

fine, car I hit had very minimal damage, mostly just a scuff. No big

deal, just annoying.

12 - 18 - 12

Bought a stock 20valve manifold off a guy on Club4AG. I'll have to

modify the outermost bolt holes, but otherwise it will bolt right up to

the head. I'll have to get a different downpipe to get it to work with

my car, but there's a guy that makes downpipes that bolt the stock SC

exhaust right up to a 20v manifold, so when I get time/money I'll order

one of those too.

Yes, the head shield looks like ass, but it will be coming off and I

will either put the shield from my stock manifold on it, or wrap it,

but I hear wrapping stock headers on some cars causes them to crack, so I

gotta ask around and see if it's OK on these. This header will be much

lighter and flow much better than the stock one.

12 - 25 - 12

Got some Christmas cash and ordered one of these to match my incoming

20v manifold. I ordered mine with the OEM style O2 sensor bung AND an

extra universal o2 sensor bung so I have the option of putting in a

wideband at some point. Both the downpipe and manifold will be

wire-wheeled and hit with multiple coats of VHT flameproof paint, and

the header and front half of the downpipe will be header wrapped (header

for obvious reasons, downpipe because it comes very close to the oil

pan). And then I'll see if I can spray the wrap with a sealant to keep

moisture out. It's gonna be sah-weet.

From the SV3 Power website:

An SV3Power original. 20V-to-SC downpipe bolts directly between any

stock 20V upper header and your Supercharged MkI MR2's stock catalytic

converter or SV3Power SC-style cat or SC-style test pipe, makes any 20V

swap easier.

Standard 2.25" OD main tubing supports approx. 165hp

at the wheels and is ideal for a Blacktop (AE111) engine. Cars making

more than that should select the 2.50" OD main tubing option.

20V-to-SC downpipe features include:

- 100% bolt-in fit w/ full OEM compatibility

- Heavy 14-gauge aluminized tubing: 1.75" OD secondary, 2.25" OD main (2.50" optional)

- Proprietary laser-cut 3/8" thick steel flanges

- Outlet flange grooved for OEM-style crush (donut) gasket

- Braided stainless flex joint for maximum flow and durability

- Stainless tubular hanger fits car's existing rubber mount

- Muffler brace in OEM location for maximum rigidity

- Choice of Toyota-style oxygen sensor pad or threaded sensor bung

- Optional rear oxygen sensor fitting for wideband or dyno visits

- OEM-grade gaskets and quality M10x1.25 hardware included

Two-bolt sensor flange has studs at 44mm center spacing, fits MR2 sensor. 20V sensor may require modification to fit.

Flanges

and welds are normally painted with VHT FlameProof primer coating;

please check the 'unpainted' option if you will be applying your own

paint or coating and do not want this applied.

Photo shows

updated design with revised oxygen sensor fitting location and longer

secondary tubes for more midrange torque. Item in photo has 2.5" tubing,

rear oxygen sensor fitting, and VHT FlameProof coating (all optional at

extra cost).

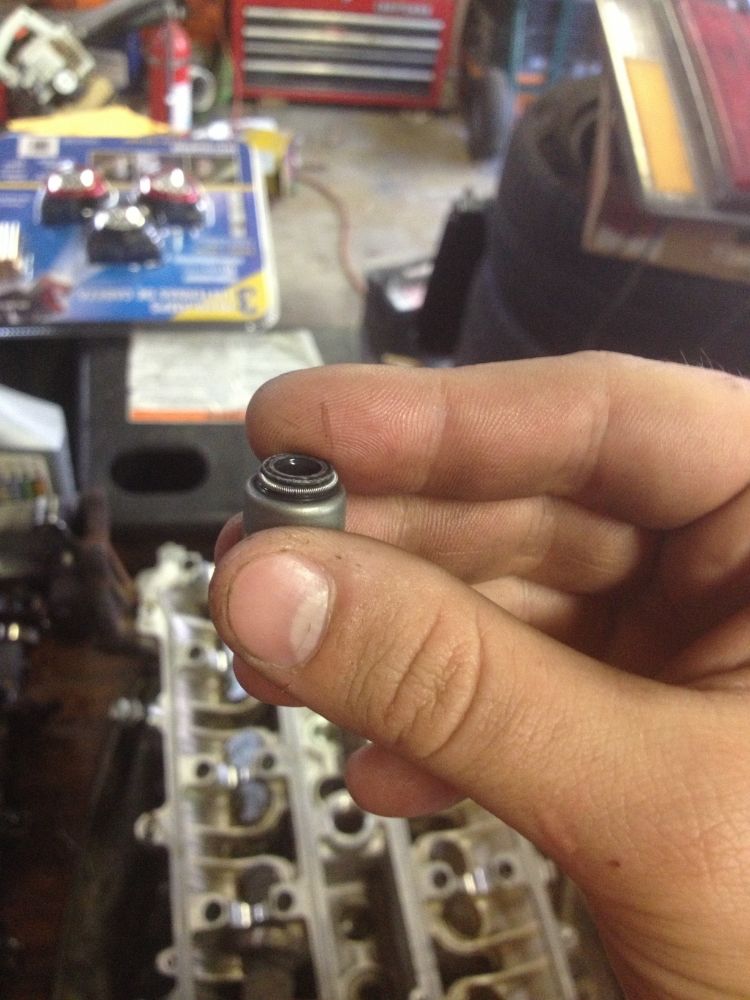

12 - 27 - 13

Manifold came in today and it's in pretty great shape. Here it is before I started cutting off the heat-shield tabs:

And I got one tab and half of another off before I nicked my knuckle

with the grinder. Pretty deep, not quite to the bone, but close. 4 hours

in the waiting room later.........

Looks like I won't be working on my car over break much. >.<

12 - 28 - 12

Tabs cut off, welds ground smooth, wire-wheeled to get the rust off

Hit it with some VHT Flameproof

Now it's on the grill curing.

12 - 30 - 12

Manifold modified to fit a 16valve head. Had to slot one bolt hole and redrill another. Now it bolts right up.

And here it is wrapped and sprayed with the moisture sealant

1 - 4 - 13

Finally ordered a Saikou Michi catch can from saikoumichi.com. I've wanted one of these for a long time now. I got a S1-OCC.

The reason the SM cans are so much better than pretty much everything

else is because rather than just being a shiny empty box with hose

fittings they actually do what they are supposed to do.

My engine has a VERY basic pcv system which is literally just a hose

going from a fitting on one valve cover straight to the intake piping

just before the throttle body. If you were to look inside my intercooler

you would see that it is completely coated with oil film. I think this

is just typical of older engine designs because the blowby on the

All-Trac was pretty bad too. Later JDM versions of the 3SGTE got factory

catch cans.

1 - 29 - 13

Catch can is installed. It took all of 10 minutes

plus a pair of ruined jeans (protip: don't accidentally kneel near a

capless can of spray paint. You will touch it. It will spray your

pants). Also, my downpipe has FINALLY shipped! If it can get here and

get itself on my engine before the dyno day, I may re-dyno the car just

for shiggles

2 - 3 - 13

250F, 350R. Yes.

Ordered them about 30 min ago

2 - 4 - 13

List of crap to do in the next couple months

Change engine oil/filter

Change transmission oil

Flush brake fluid/clutch fluid

Gut brake proportioning valve

Check all brake pads for wear

Build/install GC coilover setup

Get alignment, probably close to what I've been running, like -2/2.5 * F camber, 0 F toe, -1.5/2* R camber, 1/16 R toe in

2 - 5 - 13

2 - 9 - 13

or a while now I've been having issues with my car where sometimes when

it's cold the starter will not spin. You can hear it extend, but not

turn. Most of the time just holding the key in the "start" position

would eventually kick it on, but I finally got around to fixing it.

First you buy two of this part number: 28226-64110

Then follow these directions:

http://www.dorikaze.ca/dorikaze_guides_ ... hp?a_id=28

However

I ran into a strange issue. First things first: my car is an SC, so

it's a different starter from the NA. Second: it's not the original

starter. I don't remember the brand, but it's not Denso.

Now the

issue I hit was that on the replacement contacts, the bolt axis was on

the center line of the curve of the contact on both. In the starter, one

contact is this way, but the other is slightly offset. To fix this, I

had to elongate the hole in the housing and move the contact over about

4-5mm to get it to be aligned properly.

2 - 10 - 13

Manifold and downpipe are on. It was one of the

more frustrating experiences in recent memory. I didn't take many pics

because I was pissed off all day.

You know how sometimes there are little things that are annoying? Bolts

that are too long, have a hard time coming loose, or come loose then get

too tight then loosen up again? Hitting your head on motor mounts,

cutting/smashing/jambing hands on random hard objects. I had to install/remove

the manifold a billion times because more material had to be removed to

clear the HUGE alternator bracket that the SC has. Also I had to remove

the dizzy cap and alternator to get to one of the manifold bolts, each

of which had their own irritating issues. THEN the downpipe. Apparently

my cat is not stock so the pipe diameter of the cat and the downpipe are

different sizes and the gasket doesn't make a perfect seal. Close, but

just enough that I notice. Then, to put the whole downpipe/cat/muffler

assembly on, there wasn't enough wiggle room to put the muffler in the

hangers and slide the downpipe on the manifold studs, so I had to unbolt

the hangers from the chassis (WAY HARDER THAN IT SHOULD BE), slip them

on the muffler, bolt it up to the manifold, then jack up the muffler and

bolt up the hangers to the chassis with the exhaust already on it (WAY

WAY WAY WAY HARDER than it sounds).

There were many other things that pissed me off but that's all I can immediately remember

2 - 12 - 13

It's the little successes that really brighten

your day. I've had a rear strut assembly sitting in the garage for

months that I've tried EVERYTHING to get the gland nut off to remove the

shock insert. It's seriously one of the most-stuck nuts I've ever

messed with. So tonight I got bored and went out and figured out a way

to use an old tire iron in conjunction with a pipe to get enough torque

to turn it. I had to put it nut-first into the vice and tighten the vice

with the pipe. BUT it came out. And then I cut off the spring perch,

ground out the welds, and wire-brushed the top layer of grime off. If I

can do the same to the rest of the strut housings from the parts car I

can MASSIVELY minimize the down time for the GC install!

2 - 13 - 13

All the threaded collars are *gasp* THE RIGHT SIZE!!!

2 - 16 - 13

Took this a few days ago but forgot to post. Also, I'm really glad I

wrapped it because it's REALLY close to one of the shifter cables. Also,

I forgot how freaking close the dizzy and alternator are to the

manifold, so any protection I can give them is a plus.

It's a bit throatier sounding, maybe some slight low rpm power loss with

gains above 4k rpm. Keep in mind this header was designed for an engine

that revs to 8000+ rpm

2 - 17 - 13

Went over to Mitchell's shop yesterday to work on the 86 and I brought

along my struts. Corey came over and used a welder in the shop to weld

up the spring perches. Now I just have to prep them and paint them and

then they will pretty much be ready to go on the car. I'm thinking about

getting camber plates for rear as well to complete the setup.

2 - 20 - 13

Struts are cleaned up and ready to be painted this weekend. I'm gonna

give them the same treatment as the wheels: adhesion promoter, primer,

and bronze paint

Weights: 5 lbs each. That's just the housing with no springs or shock insert.

2 - 22 - 13

Primed

Painted with leftover bronze from my wheels:

2 - 23 - 13

Dyno'd again today. Graph is exactly the same.

Looks like the exhaust doesn't gain any power, but it is still lighter

and the wrap will cut down on underhood temps

3 - 5 - 13

Changed the trans oil and flushed the brake fluid yesterday. Also gutted

the brake proportioning valve so now I have equal brake distribution

front to rear.

Mileage is around 196k

3 - 17 - 13

Put in some fresh spark plugs. NGK BCPR6ES-11, re-gapped from 0.042 out of the box to around 0.032-0.034 in the car.

3 - 20 - 13

After multiple instances recently where I really

needed immediate supercharger-style oomph down low but didn't have it, I

finally ordered a Gruntbox so I can actually have some power under

3500rpm with that CSI spraying some extra fuel in there. Needing to

merge NOW and having to wait 2 seconds for rpm's is not acceptable on an

SC engine.

4 - 5 - 13

I bought this car 5 years ago today!

4 - 13 - 13

So I've been staring at my coilover bits about to go on and there are several things that bug me.

1.

Even though I followed the supplied directions, I don't think the

welded perches are low enough. No way to know until a test fit though.

If not, good thing Mitchell has a welder now, so I can just grind it

down and re-position them.

2. I might need to get some helper springs

but they aren't cheap. Most people just go without, but if it's not TOO

expensive, I may go ahead and do that after some test fitting.

3.

How the T3 camber plates interact with the upper spring hat baffles me. I

have two different kinds of hats: the GC-supplied flat ones, and some

conical ones I bought for (relatively) cheap from T3. Now, T3 also makes

a "camber plate" upper hat, but from the picture on their site it

doesn't look like it solves my issue, so I've emailed Gabe about it.

This is what I said to him that describes the issue:

"Hey there,

I am currently piecing together coilover stuff for my

88 AW11 MR2 SC. I have the typical Ground Control weld-on stuff with GC

springs, Koni shocks, and your awesome T3 camber plates, all just

waiting to go on the car. However, after looking at how the upper spring

hat and the camber plate will interact, I have been trying to figure

out the best way to make this work. I have the standard GC-supplied flat

upper hats, but I saw that that wouldn't work because then the upper

hat will be hitting the bottom of the camber plate at a weird angle on

the front where I am running a bit of caster. So I ordered a set of

conical upper hats from you guys to see if that would be a better

solution, but now it's just the top (collar is the right word I suppose)

part of the hat that will be making contact with the plate, still at a

weird angle.

I suppose my main question is: what is the main

difference with your "camber plate" upper hats besides having a bearing?

Does it have some kind of spacer that goes on top of the bearing that

fits inside the recessed part of the bottom of the camber plate and

makes contact with the pillow ball itself, thus allowing some caster

angle? Can I get a better image of a complete "camber plate" upper hat

and how it interfaces with the camber plates?

Sorry if that's super long winded, but I've been staring at these parts in my room for so long it's giving me a headache haha.

Thanks!"

Here are pictures of what I'm talking about:

GC flat upper hats

T3 "conical" hats

And here's the generic picture of the "camber plate" upper hats from

T3's website. I think they do come with a hardened spacer/washer thing

that would clear all this up, but I'm not 100% sure, and those are

$60/pair vs the $20/pair I paid for the conical ones.

"The Camber Plate Upper Hat System is available for any car using

coilovers. It can also be utilized with most other camber plates on the

market, including Cusco and Cusco-Clone camber plates.

This part is only required when using coilovers and camber plates together.

Camber Plate Upper Hat System Includes

2 upper hats

2 hardened washers

2 needle bearings

2 upper race washers"

At this point I'm getting sort of wary of the

whole GC setup. Not to mention the fact that the kit that comes from

TwosRUs (and GC themselves) is different than what T3 sells (T3 kit has

much longer threaded collars but not the part that takes up the extra

space between the front strut housing and the weld-on ring). I almost

wish I just poney'd up for BC's and was done with it. At least those

adjust ride height by moving the whole shock body to preserve travel

like coilover should, as opposed to just moving the lower spring seat

around. Plus, by the time I'm fully invested in this setup I will be

basically at the same price point anyway. Koni's are $600, GC kit was

just over $400, T3 camber plates were $180/pair so that's $360, the

conical top hats were $40, and if I need to get the T3 "camber plate"

top hats those are $120 and I'll return the conical ones. That's like

$1600 for a setup that lacks many features of "real" coilovers. I'm

aware that your typical ebay fare (D2/F2/Ksport)'s are junk for

dampening, but people seem to like the inverted higher-end BC's.

If

I can't figure out this top mount issue and get the ride height right

after some test fitting, I may just sell off all my stuff and buy the

inverted BC's.

It looks like this is the kind of thing I need. I found these on google image search.

I'd need them to be able to slip over the shock shafts. Front shaft

is 3/4", rear is 7/8". As it stands, the T3 conical hats I have are all

7/8" so they fit the rear fine, but have some free play on the front

(the opposite is true with the GC hats, they are all 3/4" and don't fit

on the rear shafts). I think that if I could find the weird spacer

things like in the pictures, in the right sizes to fit over the shock

shafts AND deep enough to clear the camber plates, combined with the T3

"camber plate" top hats with the needle bearings in them (assuming they

too can be made in the right sizes), would be a perfect solution.

I'm going to email Gabe and see what they say.

5 - 1 - 13

I ordered four of these little guys. I think some combination of these, a

washer, and maybe a little bit of machining on the camber plate should

work

http://www.jegs.com/i/JEGS-Performance-Products/555/64205/10002/-1?parentProductId=1299641

LATER THAT DAY

Got a response from Gabe at Techno Toy Tuning

"For the front it is best to use these:

https://technotoytuning.com/toyota/aw11 ... m-aw11-mr2

The

setup you are talking about would focus the complete weight of the car

on the bearing in the camber plates. This would put the bearings in an

axial load and constantly try to drive them out of socket. This is why

camber plates typically start making noise fairly quickly.

You are correct that it would give the best full articulation, but at a cost of noisy and quickly damaged camber plates.

We

put our swivel bearing hats directly against the gold block. The 4

parts of the swivel hat handle the camber articulation reasonably well,

put the full weight of the car on the gold block, and free up steering.

The needle bearings do take more load on one side than the other, so end

up being a sacrificial part, but they generally last 3 to 4 years of

daily driving and keep the camber plates quiet. I only send a few sets

of needle bearings out a year as replacements out of hundreds of sets of

camber plates sold per year.

Out back you don't need any turning

motion at all. I would suggest a thick rubber washer between the flat

upper hats you have and the gold block.

The rubber washer will

handle the minimal camber angle fine, and keep metal on metal noise

down. Again, focusing the weight on the gold block and preserving the

bearing in the gold block.

Whatever upper hat you use, it should be free floating up and down the shock shaft.

The rear shock shafts you have are likely 22mm, the front 20mm.

If

using a 22mm bore hat on a 20mm shaft, you will not get any undue slop

or noise. We've done it plenty of times with no poor results.

Please let me know if you have any more questions."

Then I replied:

"I hadn't really thought about wearing the

bearings, I guess I thought that's how it was designed? My main concern

with this was the angle created when there is extra caster dialed in,

but I just looked closer at the car and the front strut mounts are not

vertical, and in fact already tilt back quite a bit, minimizing the

would-be angle between the plate and upper hat. Maybe I'm worrying about

nothing?"

5 - 5 - 13

New cat is in. It's a Magnaflow universal cat with Toyota flanges welded

on by SV3Power.....flanges that are actually the right size and seal

properly. Imagine that.

5 - 6 - 13

My to-do list for this car

Remove muffler, prep, paint, reinstall

Install Gruntbox (whenever it comes in)

Install/adjust coilovers

Adjust sway bars to compensate

Get alignment

Front: -2 or 2.5* camber (whatever it's running now, I don't remember)

Max caster (something like 6.5 - 7*)

0 toe

Rear: -1.5* camber

0 toe

Remove gutted brake prop valve housing and replace with fittings

Completely rewire fog lights

5 - 7 - 13

Took the T3 camber plate upper hats over to the Ju house and used the

drill press to drill the holes that will be used to zip-tie them to the

top of the springs. Aluminum is MUCH easier to drill than steel, by the

way.

5 - 16 - 13

New aux input cable (now standard 1/8" instead of old iPod 20-pin) and the GruntBox

The ipod cable in my car is breaking on the inside. It no longer charges

the ipod, and it occasionally stops sending signal to the left side of

the car. Plus it doesn't work on newer ipods/iphones for some reason.