called NAPA today. apparently the guy that does valve work was on vacation last week so they still haven't gotten to it.....yeah......so im more than slightly pissed.

7/1/11

7/10/117/1/11

just heard back from NAPA machine shop. all the valvetrain parts are in good shape and the valve job/resurfacing should be done tomorrow. I'll be picking it up on Tuesday!!!

7/5/11

the head came out SUPER clean. so shiny.....got a TON done today. will add deets later but toooooo tired now

7/6/11

ok the first thing I did was try to put in the ARP headstuds. started by blowing out the holes in the block with compressed air. most of the studs went in fine but two or three wouldn't go in all the way, so I ended up going to Sears and getting a tap set and chasing the threads which worked really well. Head went on (this is all very abbreviated by the way), and then cams went on, set everything to TDC, timing belt changed, got the exhaust mani on +heat shields, alt and AC brackets, alternator, intake mani, water outlet/bypass, fuel rail, fuel lines connected, EGR on.

issues encountered - biggest was the expected ARP headstud/distributor shaft clearance issue. I had to grind the mess out of the end of the dizzy shaft and it still BARELY fits. I MAY have to end up grinding more but for now I think it will be ok.

Tomorrow could possibly see the rest of the parts being assembled.

7/6/11

was making good progress today till it decided to monsoon for 15 min....just long enough for me to get everything put away >.<

fuck it....lunch break.

7/7/11

I got EVERYTHING installed today. literally. its all in. it ran for 5 seconds tonight. however it was making a HORRIBLE noise from the dizzy area so I'm gonna remove it again and keep grinding the shaft so it wont hit the head stud.

Tomorrow is oil change and coolant flush. and re-install engine lid/strut bar/scoop, etc. Then maybe it will be done.

except for a wash. the car is FILTHY

Quaife QSR came in.

today. SUCKED. so hard. got up, ground down the dizzy more to make it fit right. start it up and it STILL sounds like someone threw a rock into a garbage disposal. long story short, things get taken off and put back on and taken off a half a dozen times, crank pulley bolts back themselves out, water pump pulleys forget to be tightened and then end up needing to come back off anyway....timing belts have to be removed again....

turns out NAPA is great with machine work but SUCKS at adjusting valve clearances

the BGB says that on a cold engine the Intake valve tolerance is 0.15 - 0.25mm

Exhaust valve tolerance is 0.20 - 0.30 mm

here is a text diagram of what I found after corey lent me his handy dandy feeler gauges:

Exhaust

_____0.340__0.356__________0.330___0.381______0.315__0.330______0.406___0.457__________#4_____________________ #3_________________#2_________________#1

_____0.265__0.254__________0.229___0.279______0.254__0.229______0.254___0.178

Intake

7/5/11

the head came out SUPER clean. so shiny.....got a TON done today. will add deets later but toooooo tired now

7/6/11

ok the first thing I did was try to put in the ARP headstuds. started by blowing out the holes in the block with compressed air. most of the studs went in fine but two or three wouldn't go in all the way, so I ended up going to Sears and getting a tap set and chasing the threads which worked really well. Head went on (this is all very abbreviated by the way), and then cams went on, set everything to TDC, timing belt changed, got the exhaust mani on +heat shields, alt and AC brackets, alternator, intake mani, water outlet/bypass, fuel rail, fuel lines connected, EGR on.

issues encountered - biggest was the expected ARP headstud/distributor shaft clearance issue. I had to grind the mess out of the end of the dizzy shaft and it still BARELY fits. I MAY have to end up grinding more but for now I think it will be ok.

Tomorrow could possibly see the rest of the parts being assembled.

7/6/11

was making good progress today till it decided to monsoon for 15 min....just long enough for me to get everything put away >.<

fuck it....lunch break.

7/7/11

I got EVERYTHING installed today. literally. its all in. it ran for 5 seconds tonight. however it was making a HORRIBLE noise from the dizzy area so I'm gonna remove it again and keep grinding the shaft so it wont hit the head stud.

Tomorrow is oil change and coolant flush. and re-install engine lid/strut bar/scoop, etc. Then maybe it will be done.

except for a wash. the car is FILTHY

Quaife QSR came in.

today. SUCKED. so hard. got up, ground down the dizzy more to make it fit right. start it up and it STILL sounds like someone threw a rock into a garbage disposal. long story short, things get taken off and put back on and taken off a half a dozen times, crank pulley bolts back themselves out, water pump pulleys forget to be tightened and then end up needing to come back off anyway....timing belts have to be removed again....

turns out NAPA is great with machine work but SUCKS at adjusting valve clearances

the BGB says that on a cold engine the Intake valve tolerance is 0.15 - 0.25mm

Exhaust valve tolerance is 0.20 - 0.30 mm

here is a text diagram of what I found after corey lent me his handy dandy feeler gauges:

Exhaust

_____0.340__0.356__________0.330___0.381______0.315__0.330______0.406___0.457__________#4_____________________ #3_________________#2_________________#1

_____0.265__0.254__________0.229___0.279______0.254__0.229______0.254___0.178

Intake

went to Toyota this morning with a box of doughnuts to give to the two parts guys that have been helpin me out. turns out its a different guy that works weekends...anyway long story short he was grateful for the doughnuts and ended up turning the $13.50/shim into $6/shim with his employee discount. for. the. win.

7/15/11

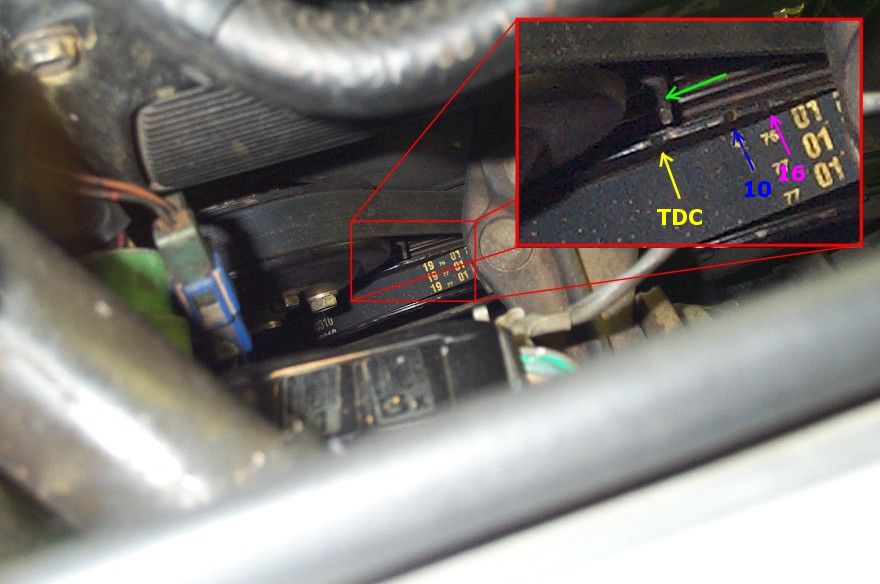

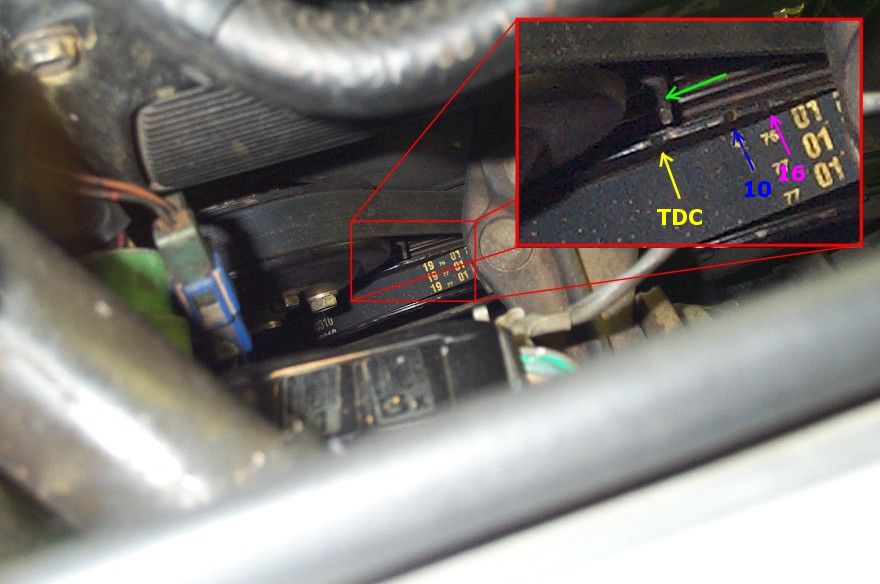

ok I think i figured out why I could not get the timing belt lined up.....I was putting it on the wrong mark for TDC

I was putting it on the middle ish one.

I was putting it on the middle ish one.

DERP

well now its all back together but it still feels/sounds like the dizzy is still off a tooth.....also I think one or two of the intake valves is out of adjustment....still really loud in a few spots, but definitely better than before

8/3/11

after checking and fine-tuning valve clearances at least 5 times, the valvetrain is still SUPER loud......and the car can't sustain idle....but i think that one is because the dizzy may be off a tooth again....

..................

just checked clearances again. everything was within spec, but just for sanity's sake I changed some to be more towards the middle or tighter end of the spec range. Sounds a bit WORSE now.....I'm seriously thinking about just giving up and limping the car to Toyota and throw my nonexistant money at them to make them do it

8/6/11

7/15/11

ok I think i figured out why I could not get the timing belt lined up.....I was putting it on the wrong mark for TDC

I was putting it on the middle ish one.

I was putting it on the middle ish one.DERP

well now its all back together but it still feels/sounds like the dizzy is still off a tooth.....also I think one or two of the intake valves is out of adjustment....still really loud in a few spots, but definitely better than before

8/3/11

after checking and fine-tuning valve clearances at least 5 times, the valvetrain is still SUPER loud......and the car can't sustain idle....but i think that one is because the dizzy may be off a tooth again....

..................

just checked clearances again. everything was within spec, but just for sanity's sake I changed some to be more towards the middle or tighter end of the spec range. Sounds a bit WORSE now.....I'm seriously thinking about just giving up and limping the car to Toyota and throw my nonexistant money at them to make them do it

8/6/11

The MR2 is alive! runs and drives! needs a front end alignment but other than that....it's pretty sweet!

8/7/11

8/7/11

timing belt tensioner was not tensioning, so the timing belt was flapping around inside the plastic covers.

8/9/11

I kinda tweaked the TRD specs.....I asked for -1.5* instead of just -1* and 1/16 toe in instead of 1/8

8/9/11

I really need to reflush the cooling system. I may do that tomorrow...may not. I do know the alignment shop gave me positive camber today, not negative, so I'm going back tomorrow to make them fix it

I kinda tweaked the TRD specs.....I asked for -1.5* instead of just -1* and 1/16 toe in instead of 1/8

Alignment done. Techs = awesome. Desk Jockey's = super lame.

8/12/11

--> roller bearings so no more wear!

--> solid so no more clevis dampener wearing, bending or breaking

--> totally eliminates the clutch pedal squeak from worn components

--> slightly longer for that extra bit of adjustment

--> threaded all the way through for maximum adjustment possibilities

--> fits MK1 and MK2 (not sure about MK3)

--> MADE IN THE USA!!!"

http://i303.photobucket.com/albums/nn146/garagecrw/03232011523.jpg

http://i303.photobucket.com/albums/nn146/garagecrw/03232011524.jpg

http://i303.photobucket.com/albums/nn146/garagecrw/04102011564.jpg

http://i303.photobucket.com/albums/nn146/garagecrw/04102011565.jpg

"** modification of the clutch pedal is required to fit the clutch pedal roller bearing. drill bit size to use is either 31/64" or 15/32" either will work but the 31/64" is a little more precise"

gonna put it on tomorrow.

8/19/11

whelp found why my clutch was squeaking. the pin that connects the pedal to the master cylinder rod looked like this

this had also elongated the hole in the pedel itself so it was making for a ton of slop movement.

this had also elongated the hole in the pedel itself so it was making for a ton of slop movement.

so now my pedel feels smoother and much firmer. also my engagement point feels higher now because of the increase in accurate pedal feedback, so that means I'm probably due for a new clutch within a year or so....which will probably be done along with a Fidenza aluminum flywheel and ARP flywheel bolts

8/25/11

8/12/11

ordered 949Racing lug nuts. the ones I'm currently using are pretty crappy quality and tend to bend and crack.

8/19/11

someone on MR2OC put these together and sold them as kits. bought it because it will fix my squeaky clutch pedal once and for all.

"--> billet aluminim constriuction8/19/11

someone on MR2OC put these together and sold them as kits. bought it because it will fix my squeaky clutch pedal once and for all.

--> roller bearings so no more wear!

--> solid so no more clevis dampener wearing, bending or breaking

--> totally eliminates the clutch pedal squeak from worn components

--> slightly longer for that extra bit of adjustment

--> threaded all the way through for maximum adjustment possibilities

--> fits MK1 and MK2 (not sure about MK3)

--> MADE IN THE USA!!!"

http://i303.photobucket.com/albums/nn146/garagecrw/03232011523.jpg

http://i303.photobucket.com/albums/nn146/garagecrw/03232011524.jpg

http://i303.photobucket.com/albums/nn146/garagecrw/04102011564.jpg

http://i303.photobucket.com/albums/nn146/garagecrw/04102011565.jpg

"** modification of the clutch pedal is required to fit the clutch pedal roller bearing. drill bit size to use is either 31/64" or 15/32" either will work but the 31/64" is a little more precise"

gonna put it on tomorrow.

8/19/11

whelp found why my clutch was squeaking. the pin that connects the pedal to the master cylinder rod looked like this

this had also elongated the hole in the pedel itself so it was making for a ton of slop movement.

this had also elongated the hole in the pedel itself so it was making for a ton of slop movement.so now my pedel feels smoother and much firmer. also my engagement point feels higher now because of the increase in accurate pedal feedback, so that means I'm probably due for a new clutch within a year or so....which will probably be done along with a Fidenza aluminum flywheel and ARP flywheel bolts

8/25/11

so the conical end on the 949Racing lug nuts is too big for the holes in my wheels. $55 down the drain...can't use em. SO pissed right now

No comments:

Post a Comment